Established enterprises have delivered a "new answer sheet" in intelligent manufacturing!

2025-04-29

The Song brocade dress worn by the hosts of the 2025 CCTV Spring Festival Gala was woven with jacquard machines developed and produced by enterprises in Changshu. The "Belt and Road Initiative" picture woven by high-end equipment from enterprises in Changshu has a pixel count over 30 times higher than that of 4K videos. Chinese-style fabrics are in high demand, and electronic jacquard machines from enterprises in Changshu are in short supply...

All these successful cases point to the same enterprise in Changshu

-- Changshu Textile Machinery Factory Co., LTD

This established enterprise was founded in 1958

Why on earth can it always lead the industry trend

Be active on the stage of The Times?

Wang Weidong

Founder of Suzhou Dongkong Automation Company

It collects image data through 3D vision photography. You can input 100 samples, and then it can actively learn and finally form a 3D vision model, which can determine the position of the specific workpiece. Then send the data of this workpiece to the robotic arm, and the robotic arm can grasp it in a timely and accurate manner. This not only saves manpower but also improves efficiency and quality.

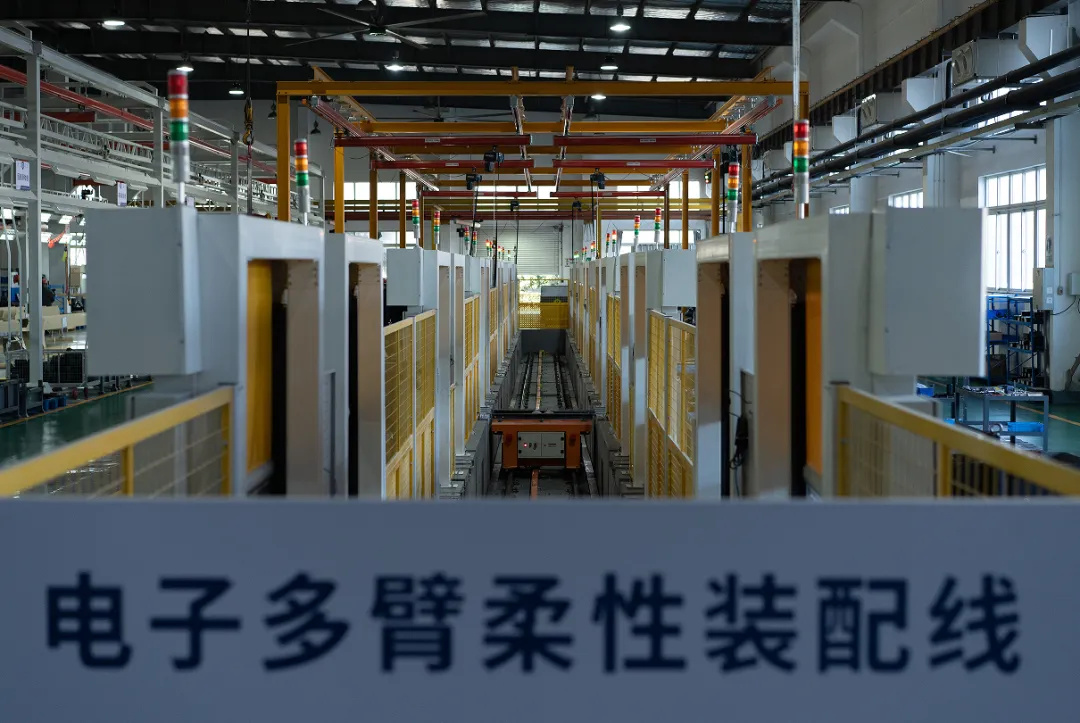

Changshu Textile Machinery specializes in the research and development and production of loom opening devices. It has successively won titles such as National Specialized, Refined, Unique and Innovative "Little Giant" and Provincial Enterprise Technology Center. Over the past nearly 70 years since its establishment, the enterprise has continuously strengthened technological innovation, filling the gap of opening devices for the rapier of shuttleless looms in China. After the new generation of rapier looms for jacquard looms without vertical shafts, which can weave Song brocade, a traditional Chinese fabric, was launched, orders have multiplied. In recent years, Changshu Textile Machinery has been actively promoting intelligent transformation, digitalization and Internet connection. Currently, two intelligent production lines have been built.

Tao Yu

Chief Engineer of Changshu Textile Machinery Factory Co., LTD

According to the order requirements, we can achieve small-batch rapid line-changing production to improve the delivery rate of orders. We will further utilize digital twin technology to establish virtual models, conduct real-time mapping and analysis of physical entities, and optimize the production process.

The successful commissioning of 3D vision figurative robots and the rapid advancement of intelligent transformation, digitalization and network connection construction are attributed to Changshu Textile Machinery's deep commitment to the innovative genes of "Artificial intelligence +" and "intelligent transformation and digitalization".

Qian Chenhui

Chairman of Changshu Textile Machinery Factory Co., LTD

Last June, after the "Chain Alliance" Shalong Changshu Textile Machinery Special event was held, China Telecom and Changshu Textile Machinery successfully connected and reached a cooperation agreement on the smart factory project. So far, they have achieved multiple results.

Li Ben

Deputy General Manager of the Government and Enterprise Department, Changshu Branch of China Telecom Corporation Limited

For many years, focusing on the research and development and production of key equipment, Changshu Textile Machinery has taken it as its responsibility to meet the needs of national and industrial development. It has benchmarking against leading international enterprises in the industry and made all-round innovations in terms of systems and mechanisms, scientific research and technology, management concepts, and distribution mechanisms.

Qian Chenhui

Chairman of Changshu Textile Machinery Factory Co., LTD