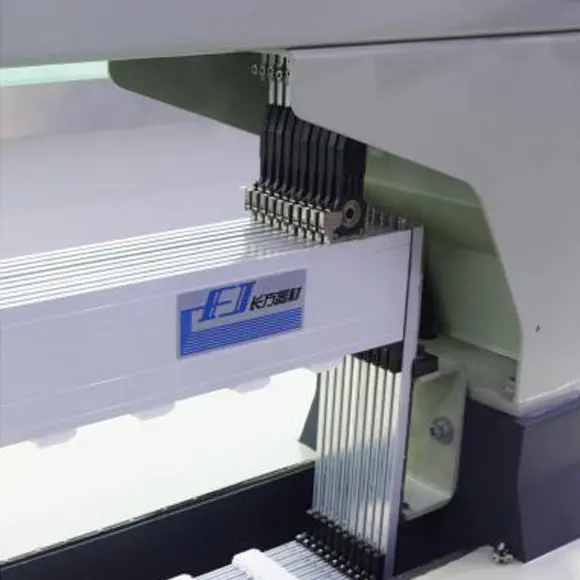

Rigging frame: escorting textile production efficiency

2025-07-25

In the field of textile production, the Harness Frame is an important part of textile equipment. Its load-bearing stability and equipment adaptability directly affect the smoothness of the production process. It plays an irreplaceable role in raw material handling, equipment installation and other links by accurately connecting textile machinery and heavy objects. It is a key support to ensure the efficient production of textiles.

Adaptation logic with textile equipment

The application of rigging frames in textile equipment is first reflected in the precise adaptation with various types of textile machinery. The equipment involved in textile production, such as carding machines and spinning machines, is large in size and has a precise structure. The design of the rigging frame needs to fit the bearing points of these equipment. Through customized connecting components, it can ensure accurate alignment during lifting or fixing to avoid damage to the precision parts of the equipment due to connection deviation. At the same time, its compact structure can adapt to the complex spatial layout of the textile workshop, will not interfere with the normal operation of other production equipment, and achieve seamless integration with the textile production line.

Relationship between load-bearing performance and production safety

In textile production, raw materials such as cotton yarn and chemical fiber rolls are often transported in batches, with concentrated weight and large volume, which puts strict requirements on the load-bearing capacity of the rigging frame. High-quality rigging frames are made of high-strength materials, which can stably bear the weight of batches of raw materials. There will be no deformation or breakage during lifting and transportation, which fundamentally prevents safety accidents such as raw material falling and equipment damage caused by load-bearing failure. In addition, the anti-slip treatment on the surface of the frame can also increase the friction with the heavy objects, prevent slipping during transportation, and further ensure production safety.

Indirect improvement of production efficiency

The efficient application of harness frame in textile equipment can indirectly improve the overall production efficiency. During the equipment installation and commissioning stage, stable load-bearing and precise connection can shorten the equipment installation time and allow the production line to quickly enter the operating state; in the raw material replenishment link of daily production, its smooth lifting operation can reduce the interval between raw material replacement and avoid the production line from stopping due to raw material shortage. This stable and reliable performance provides a strong guarantee for the continuity of textile production and makes the production process smoother and more efficient.

Changshu Textile Machinery Works Co. Ltd. has demonstrated its professional strength with its deep understanding of the textile industry. The rigging frames produced by the company fully consider the special needs of textile production, and carry out targeted optimization in terms of adaptability and load-bearing stability. They can be perfectly integrated into various types of textile equipment, providing textile companies with safe and efficient connection and load-bearing solutions, helping textile production to improve efficiency in a stable manner and promoting the sustainable development of the industry.